imagine the workshop of tomorrow.

Additive manufacturing. Machine learning. Mobile connectedness.

In the future, car dealerships will be able to 3D print needed parts, and customers will be able to track the status of their repairs. Here's how to get there.

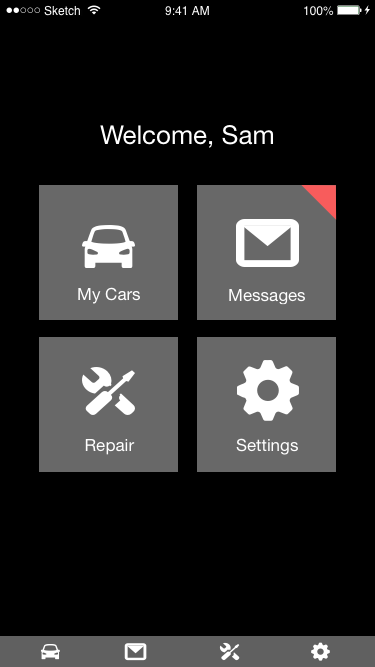

my role: developing a new servicing process & mobile app

From September 2017 to November 2017, I worked on a four-person team with two mechanical engineers and Miyeon Bae. We took a two-pronged approach to streamlining Porsche's processes: one that focused on user experience, and one that focused on integrating additive manufacturing.

Miyeon and I conducted ethnographic and user research, reconfigured the Porsche servicing process, and developed a new mobile app. The app makes use of machine learning, tracking data from repair orders to not only predict what parts of a car break most often, but also matching technicians with repair jobs that best fit their skills and availability.

Prototypes & user testing

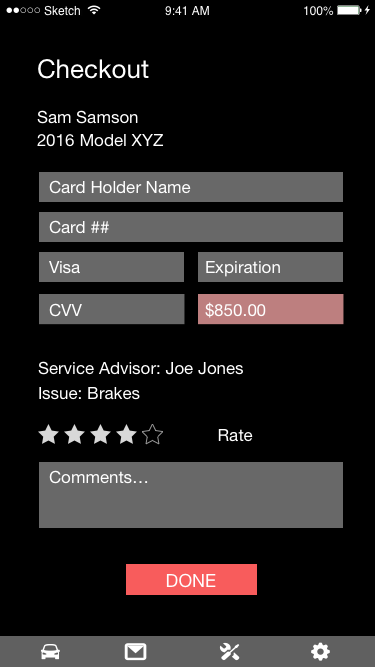

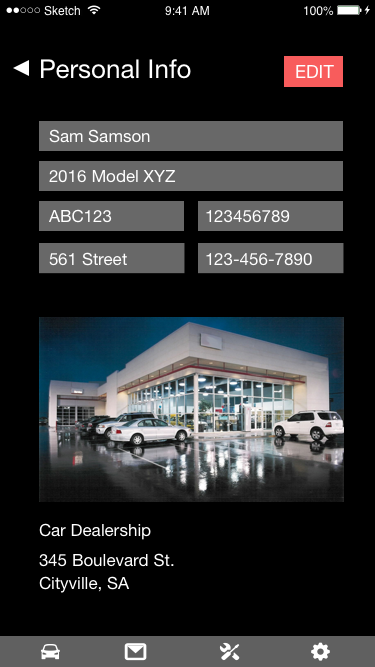

After narrowing down concepts, Miyeon and I conducted user testing, and had stakeholders try out our prototypes. I created these prototypes using Sketch and Axure RP.

product design execution

I further developed the user experience, built presentation posters, edited the product video, and assisted Miyeon with presentation slides. We presented our materials to the stakeholders, who were impressed with our new system.

user insights & needfinding

I conducted interviews with car owners, service advisors, parts specialists, and a third-party restoration specialist. I compiled these interviews into a needfinding video to illustrate to stakeholders their users' needs.

Concept generation

Each team member generated 20 concepts individually. I sketched out ideas for a mobile app, a new dealership layout, a new system process, and an Internet-of-Things system for sensors on car parts to detect problems.

the challenge: increase efficiency and customer satisfaction

Porsche dealerships repair cars dating back to the 1960s. However, classic parts that are no longer manufactured can be difficult to find. Porsche's solution is to develop a means of 3D printing those parts, but during needfinding and initial research, our team discovered a greater challenge: Porsche's communication issues slowed the repair process down, resulting in frustrated employees and dissatisfied customers.

Simply put, customers didn't trust the dealerships, and misunderstandings between technicians, service advisors, and parts specialists made it difficult to repair cars in a timely manner. Our mobile application (and the engineers' additive manufacturing process) closes the communication gap and increases trust among all parties involved, resulting in better efficiency and satisfaction.

Through needfinding and research, we identified our key stakeholders, those most invested in this process:

Car Owners: Owners need their cars to be fixed quickly and properly, but also desire more transparency from the dealership—they want to know what goes on in the repair shop and to trust the technicians working on their cars

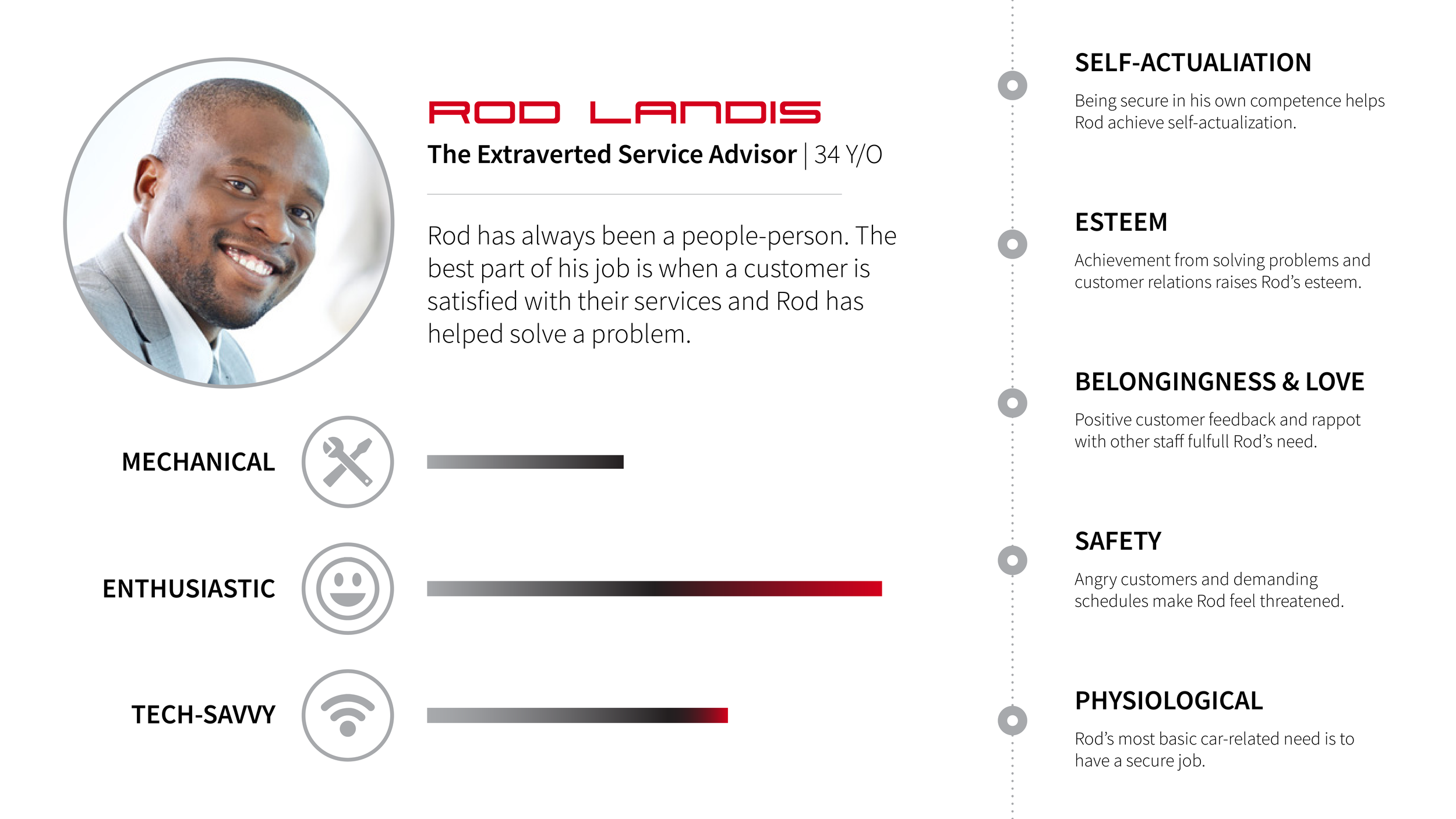

Service Advisors: As the communication point between customers and the dealership, service advisors need to be able to solve problems and maintain customer satisfaction, as well as be sure that the car is fixed in a timely manner

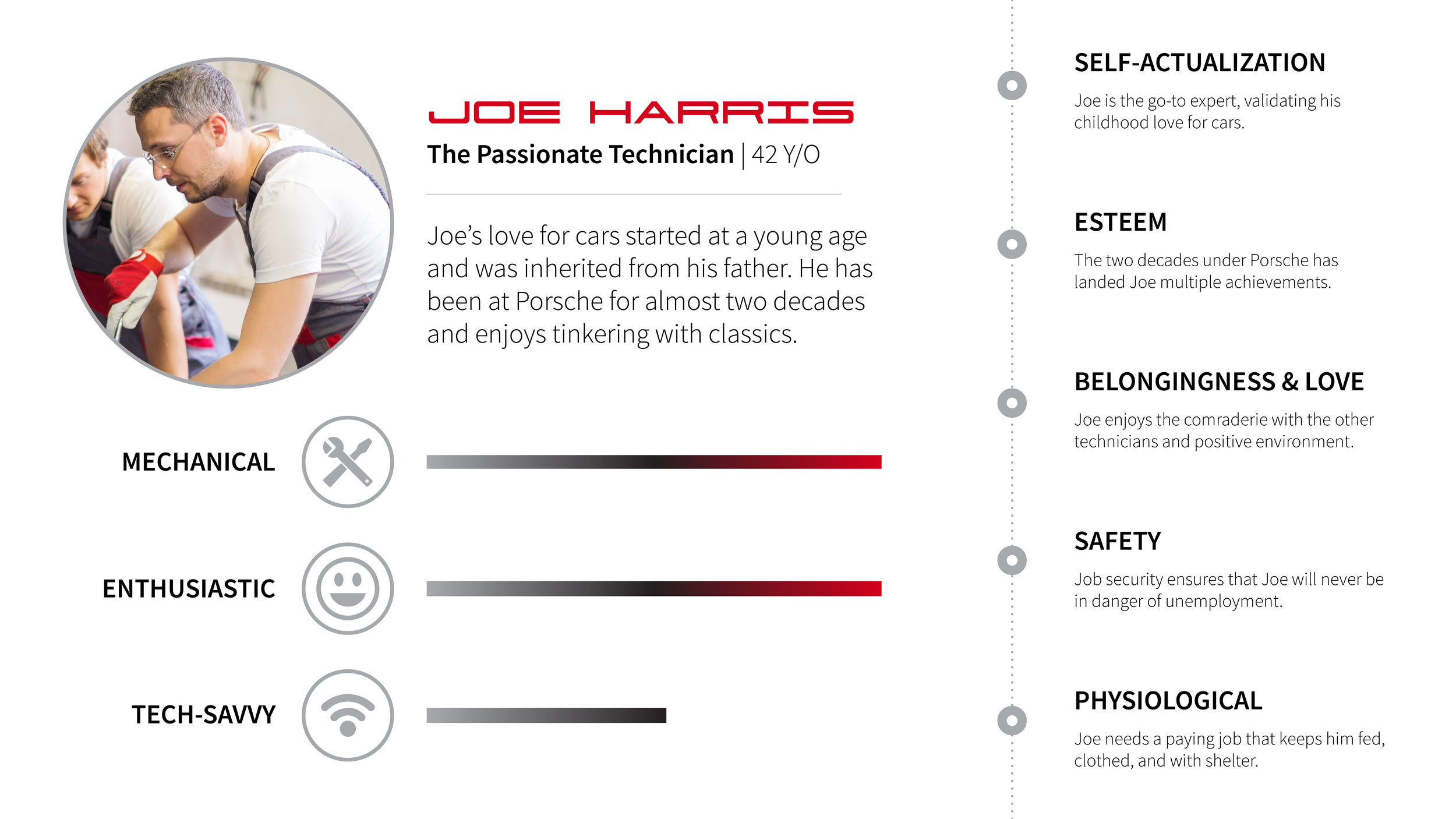

Technicians: At Porsche, technicians are paid on a flat rate, meaning they only have so much time to complete a repair job; as such, their first year juggling tools and learning the ropes tends to create stress

Parts Specialists: Parts specialists are mainly concerned with acquiring needed parts, and cannot control delays related to shipping and ordering

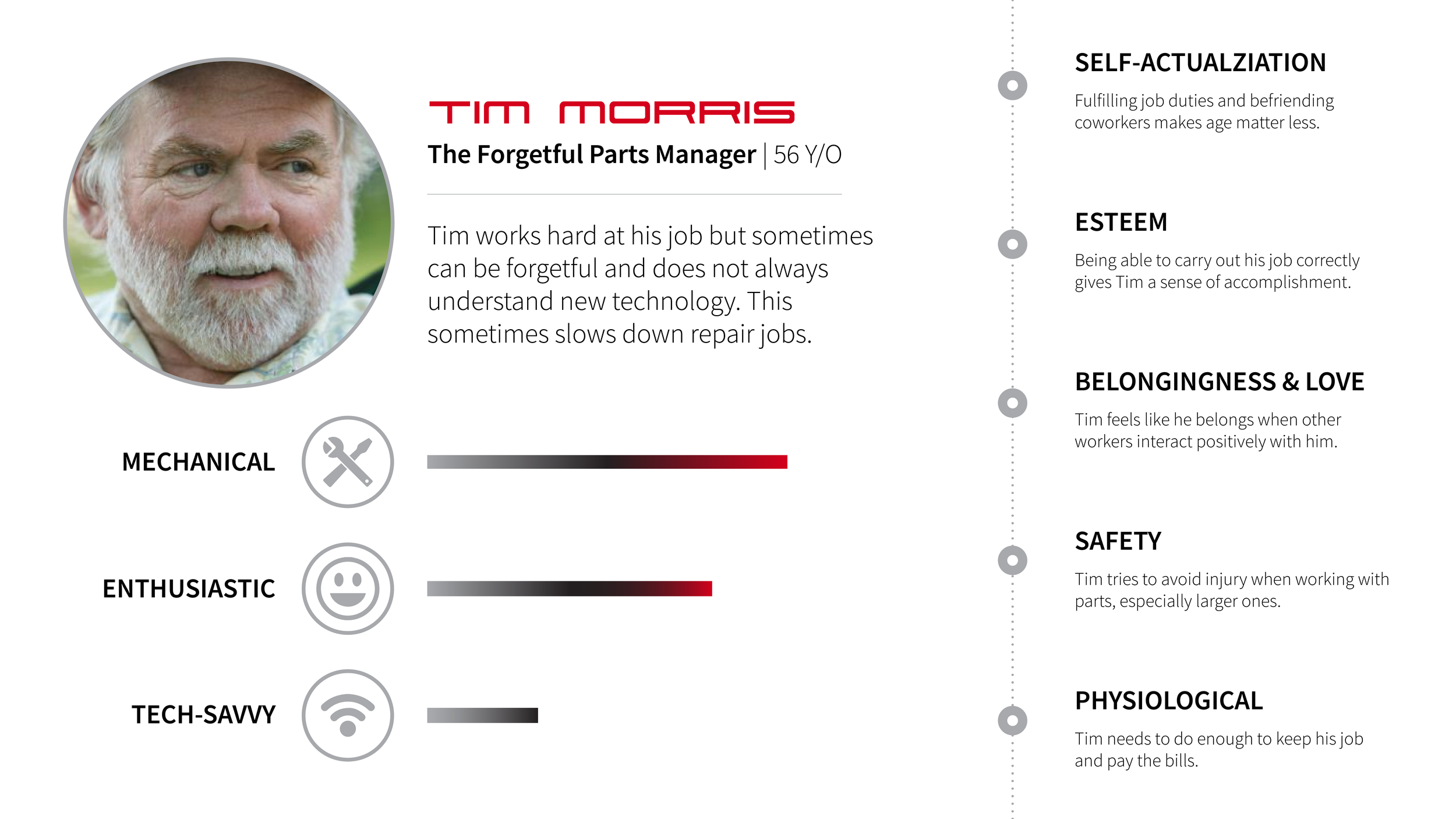

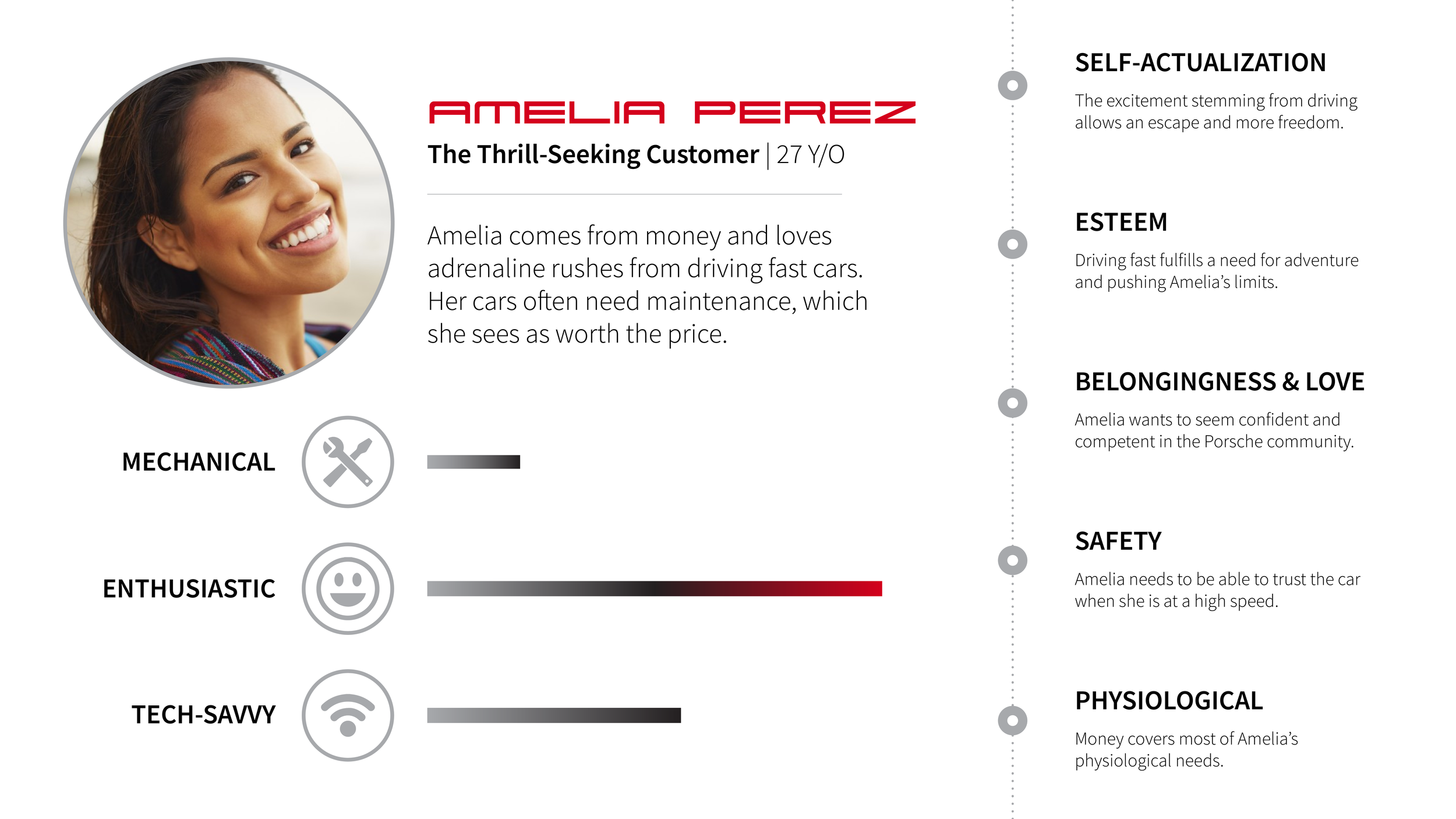

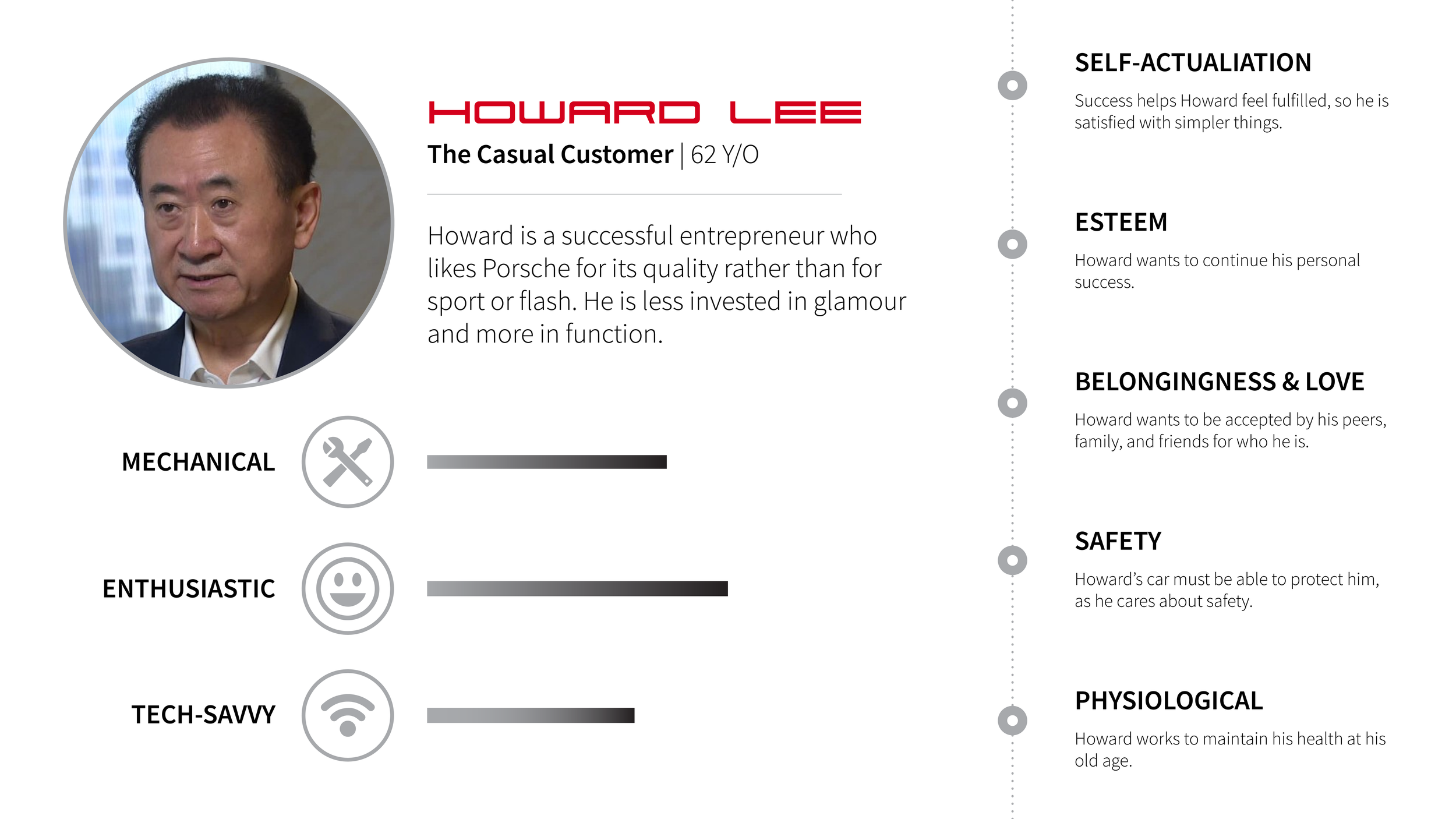

These four stakeholders were turned into six personas (below). Each persona's needs, skills, technological literacy, and attitudes were examined to give a complete picture of the different users. Two personas represent the technicians, as we noticed two general attitudes in the technicians we interviewed: those who were emotionally invested in the brand they worked for, and those who simply got the job done. One persona represents service advisors, who in general are more people-oriented and gregarious. One persona represents the parts specialist, and also covers users who are not so technologically inclined. Two personas represented two types of Porsche owners: those who are emotionally invested in the brand and do not just want a luxury car—they must have a Porsche—and those who are more casual owners and enjoy Porsche's quality but are not so obsessed with status.

Following personas, the team focused on individual needs of each user. The engineers learned industrial design methods in crafting personas through interviews, and now the industrial designers would learn engineering methods through analysis and charts. (So many charts!)

Though each stakeholder had a different set of needs, all parties were concerned with communication. Our solution would tackle communication errors and eliminate misunderstandings. The team engineers, meanwhile, began research on 3D printer capabilities and materials. These needs were synthesized into a specification table (below, left) that grouped needs into four general categories: part procurement, the need to create functional and readily available parts by 3D printing, the need to overcome communication hurdles, and the need to improve user experience. Team members came up with 15-20 ideas individually, and the most promising ideas were analyzed in an evaluation matrix (below, right) to assess how well they met specs. A 1 meant the idea improved the spec, a 0 meant it had no effect, and a -1 meant it harmed the spec. The best ideas were highlighted in red.

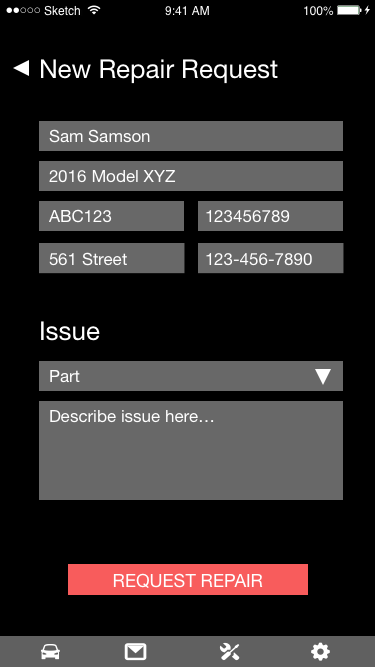

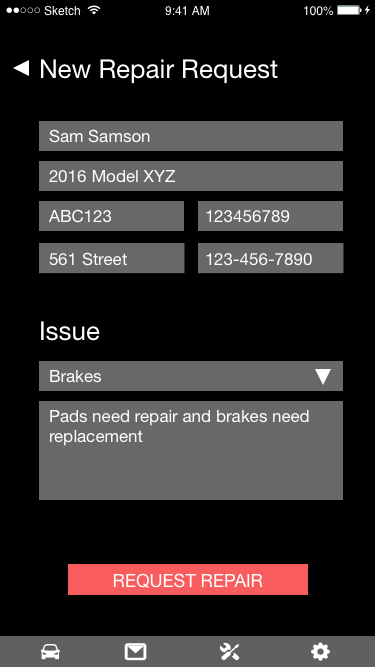

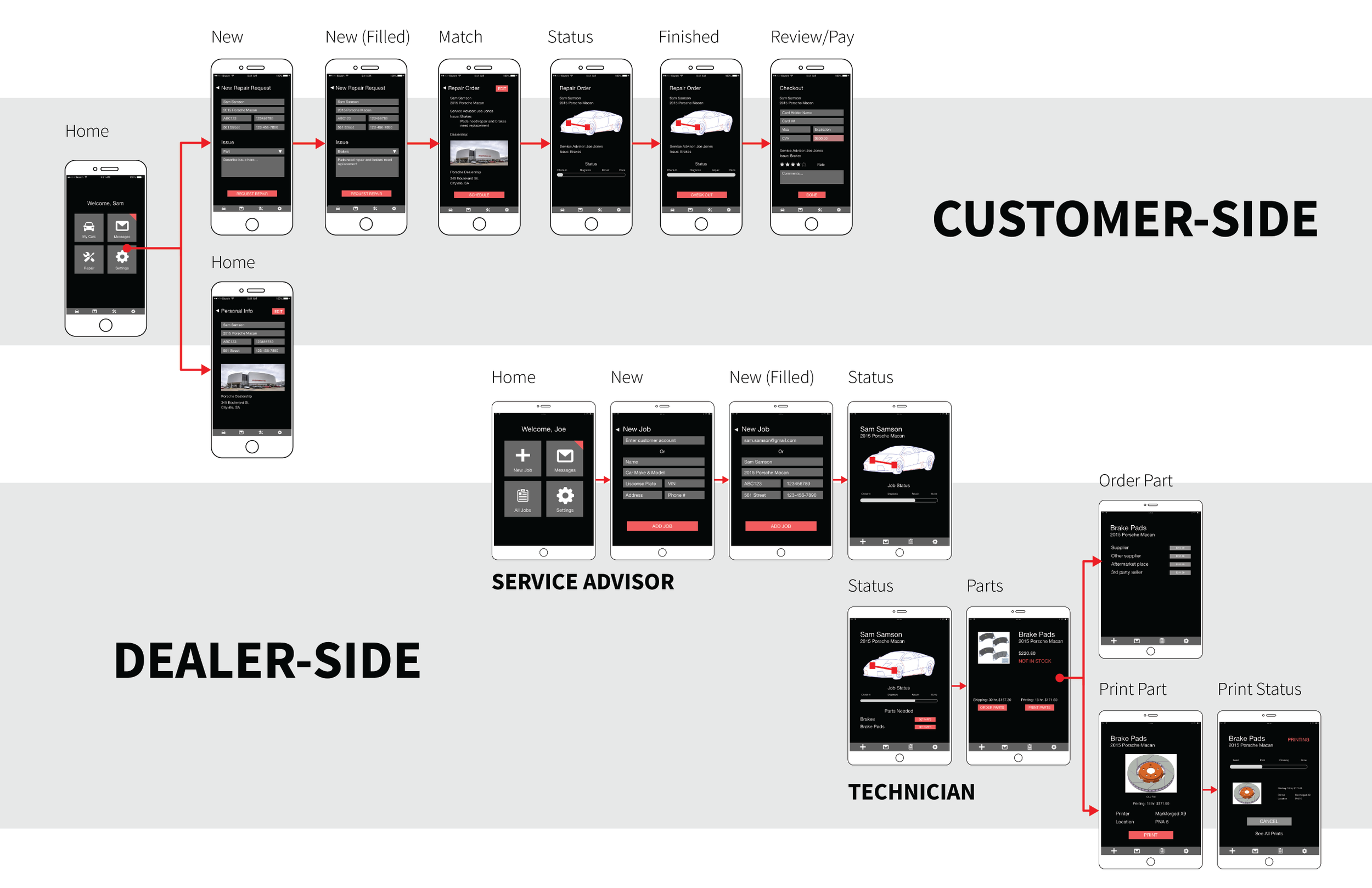

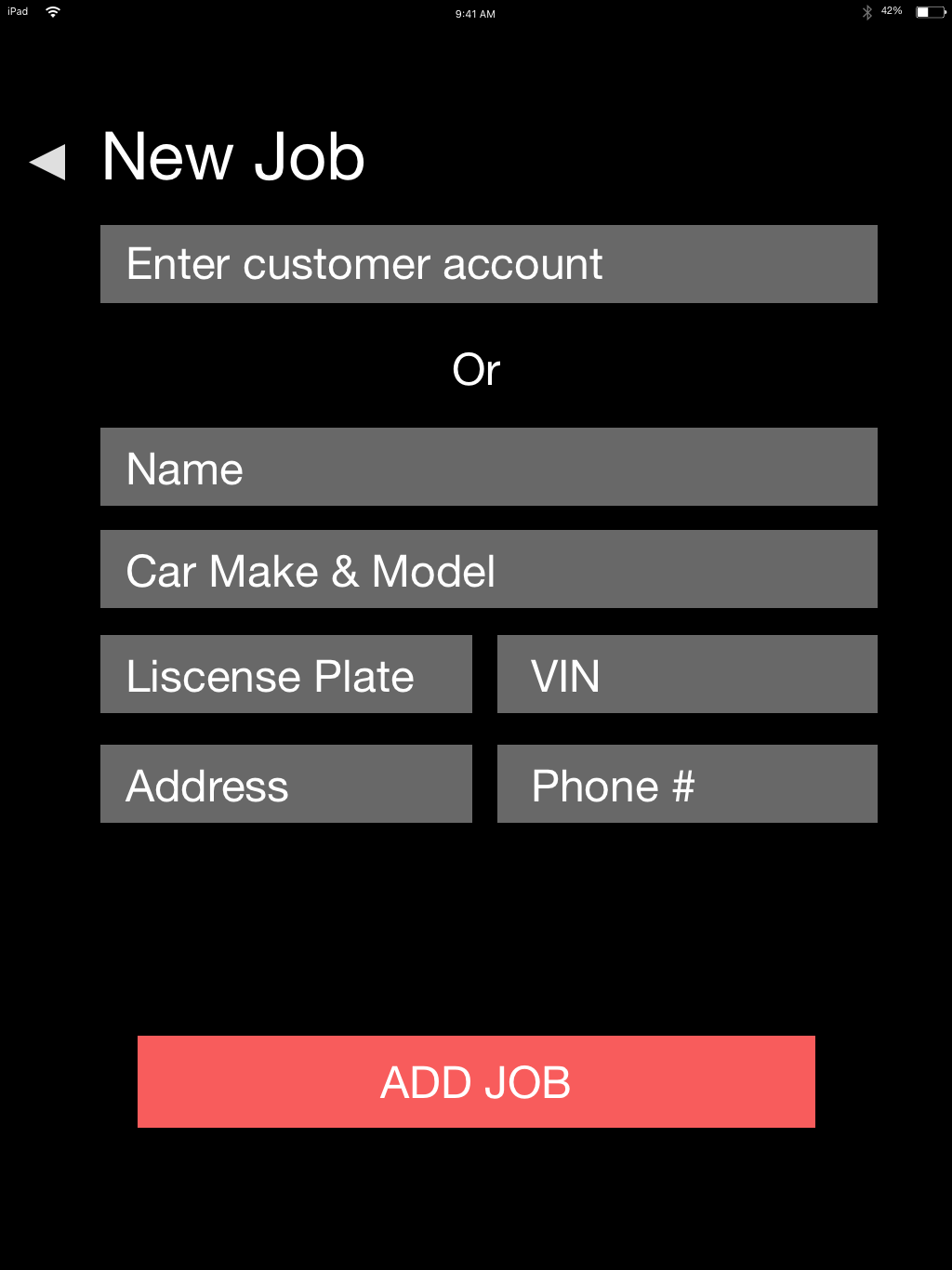

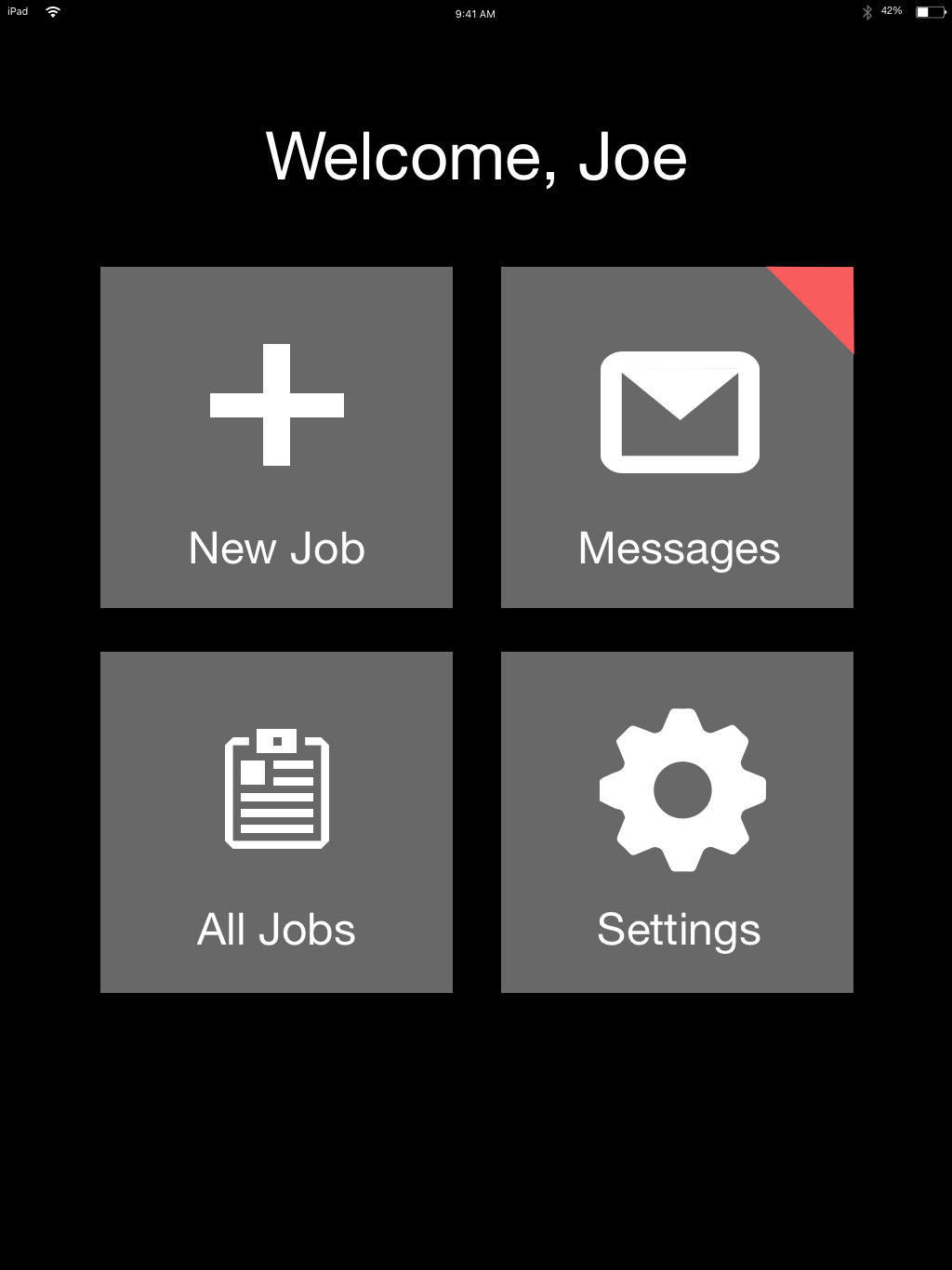

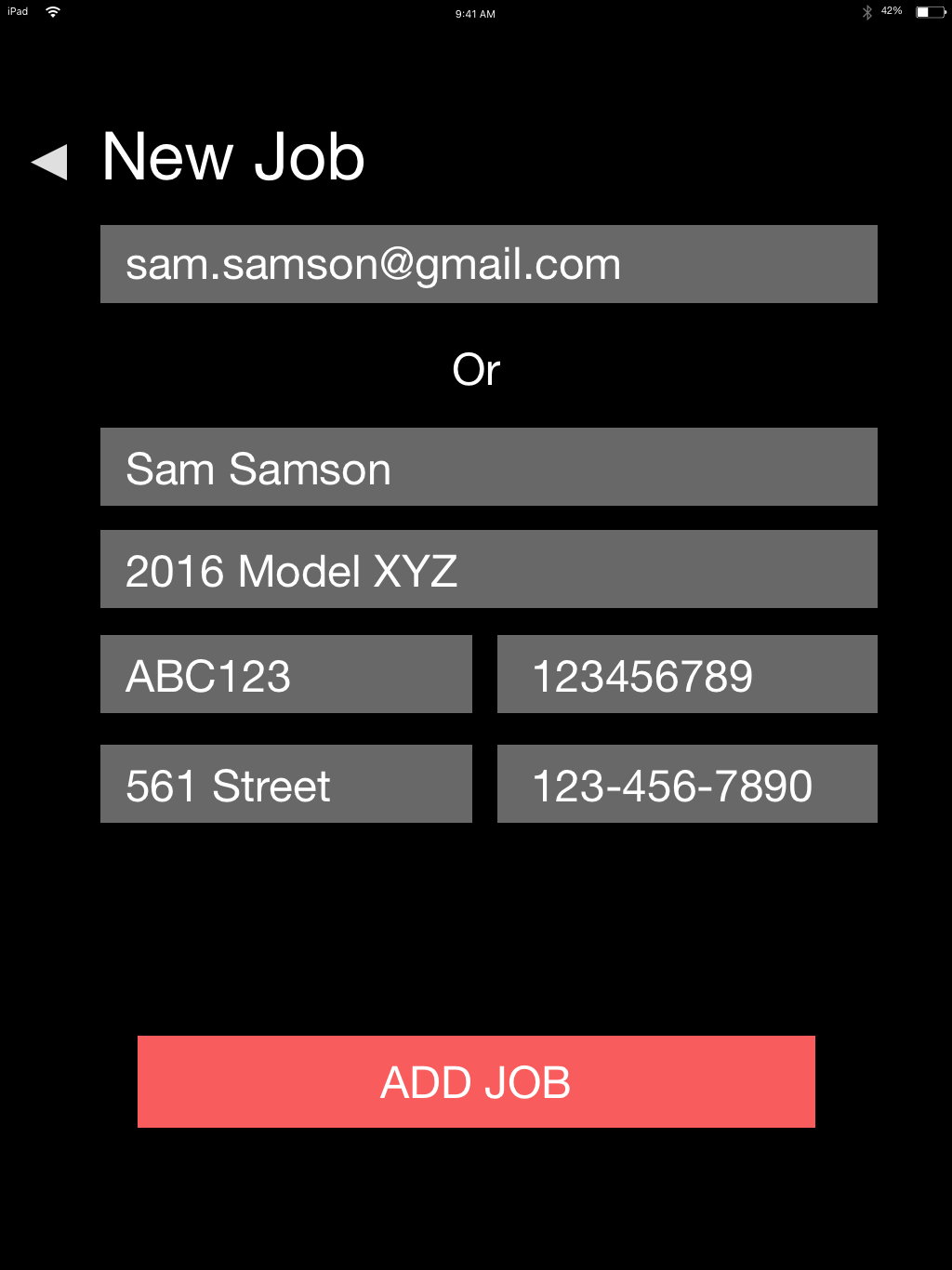

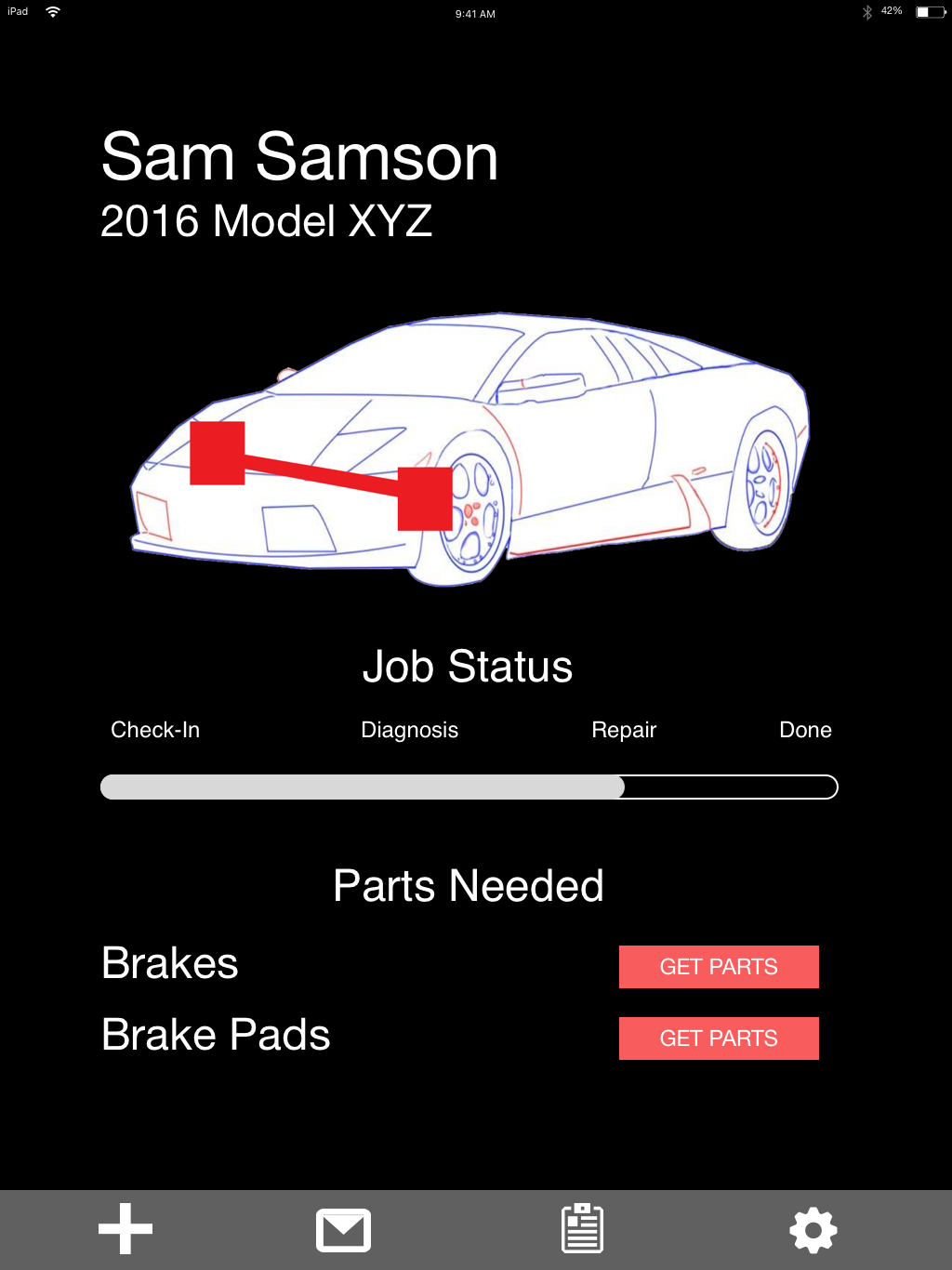

I was tasked with developing an idea for a mobile phone or tablet app. The tablet idea came from a service advisor we interviewed during needfinding. The service advisor described how he had to walk across the dealership to the parts department whenever he needed to discuss something with them, and how he had to use two different softwares at the same time: one for interfacing with the customer, and one for interacting with the other dealership personnel. A combined version of those two softwares on a portable device would solve these communication and inefficiency issues. Using Sketch and Axure, I mocked up wireframes that give a basic exploration of how this app would be structured. These basic screens and user flow can be found below.

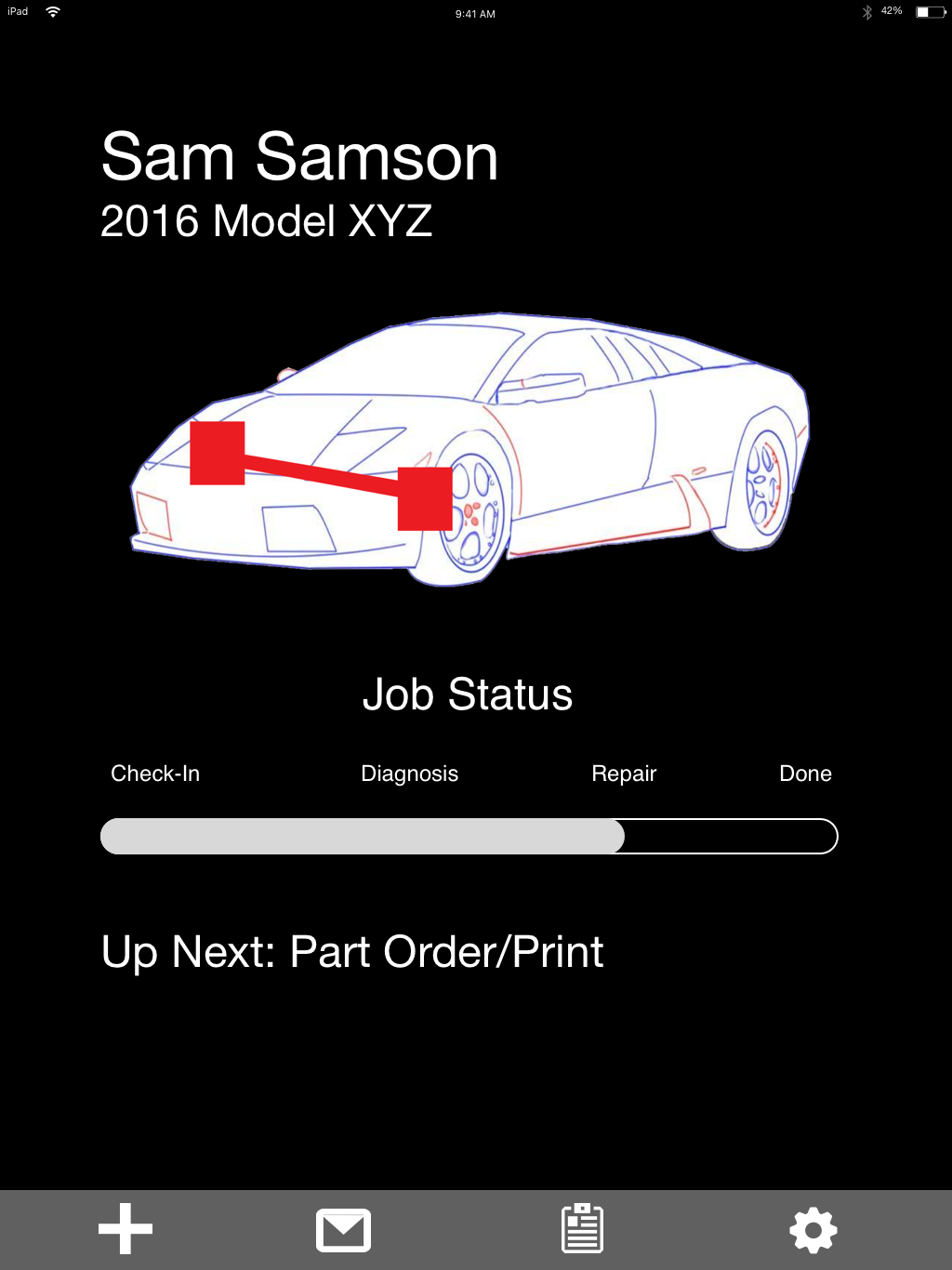

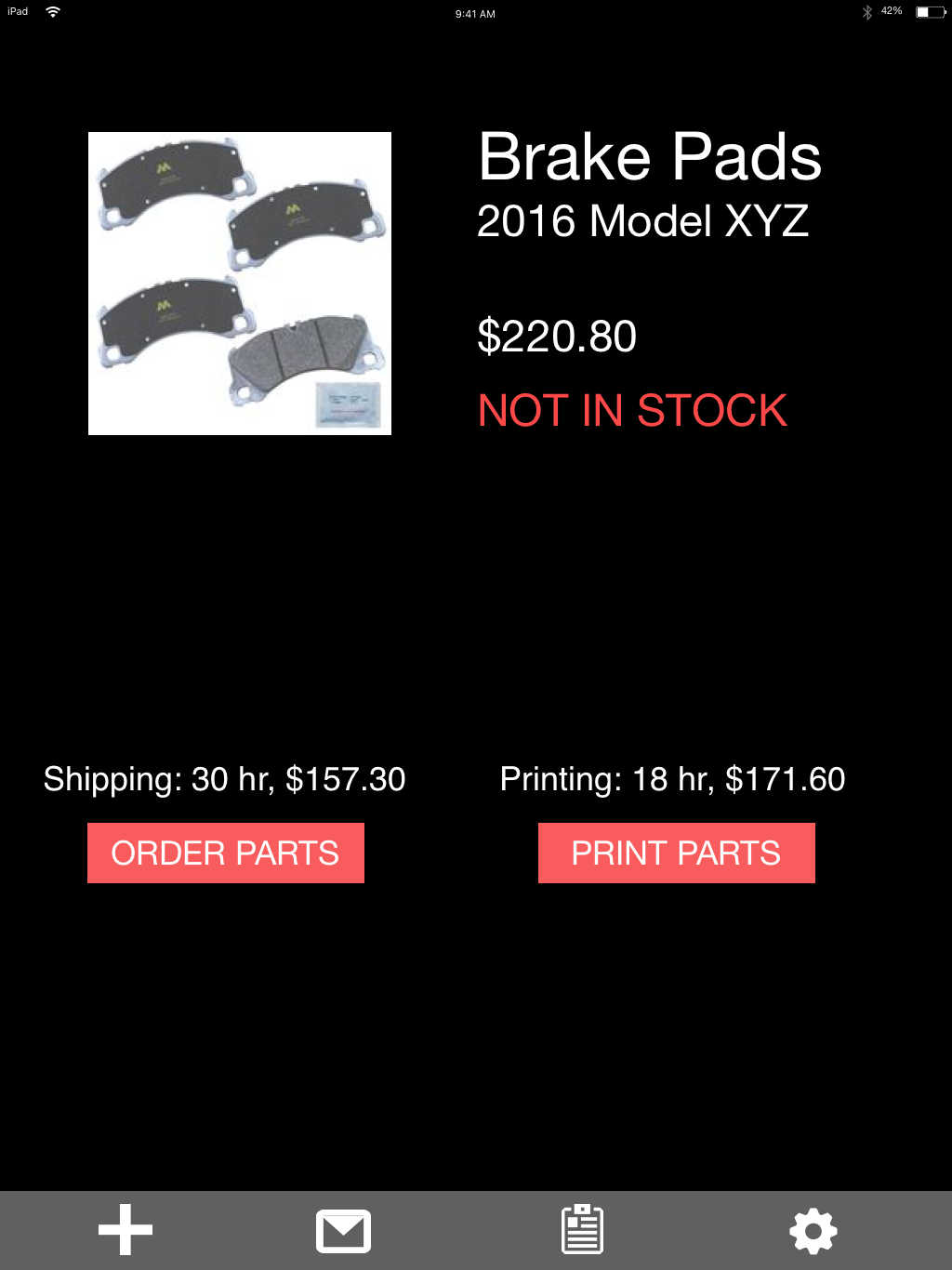

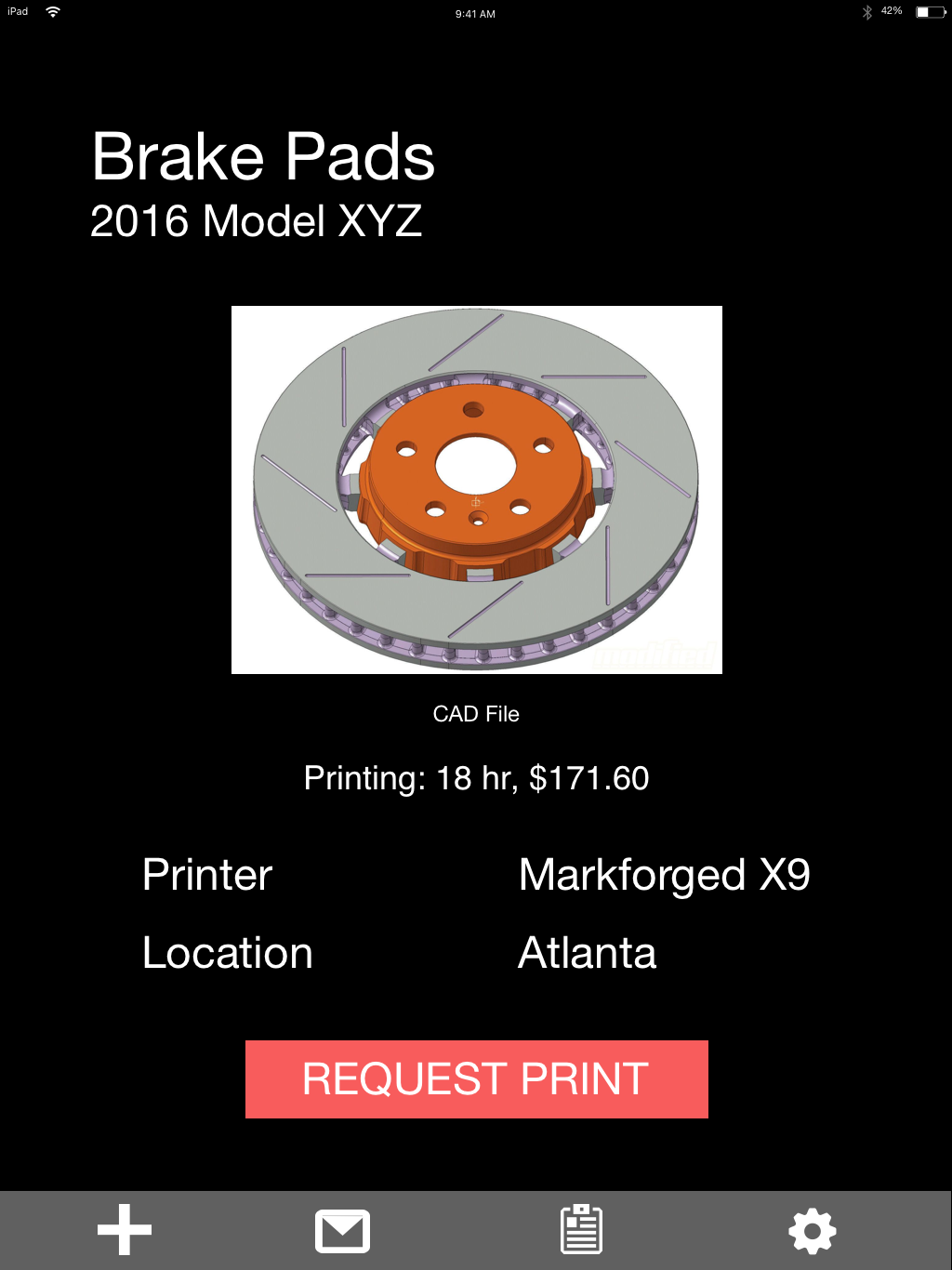

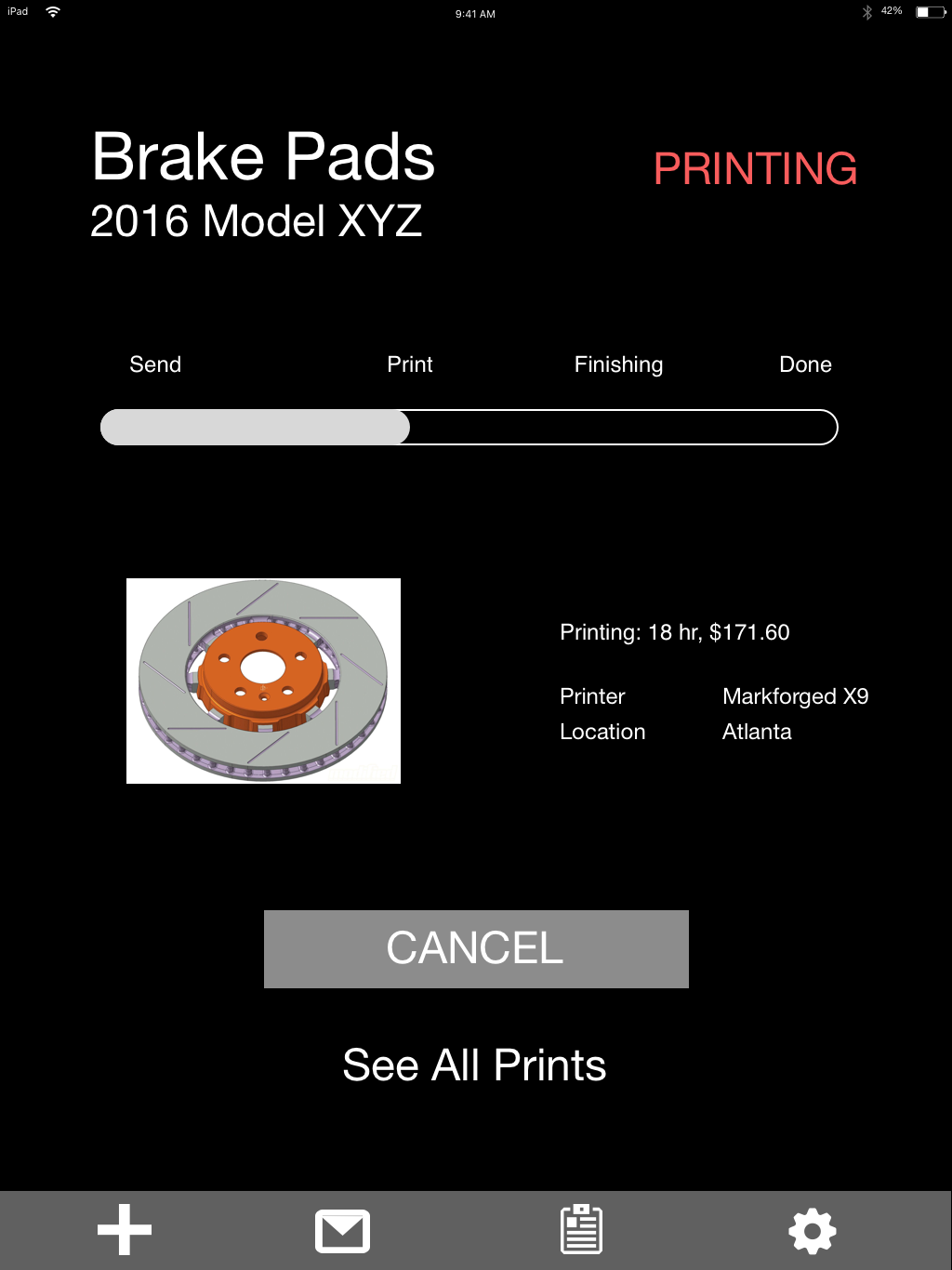

The key benefit of the app is that it provides a feature to help the technician or service advisor determine whether additive manufacturing or ordering a part would be the timeliest or most cost-effective option. The app stores data about shipping times and costs and additive manufacturing times and costs, and displays this information so the service advisor or technician can make a decision.

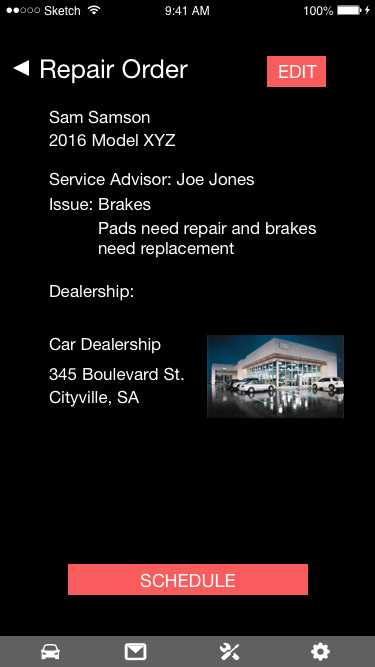

Miyeon and I tested our prototypes with users. Miyeon was tasked with creating a kiosk that uses machine learning in collecting data for predictive maintenance, and users enjoyed her prototype's predictive capabilities. In general, users liked how my app streamlined the process and connected the customer directly with the dealership so that the customer has some idea of where their car is in the repair process. This increases transparency and dealership trust. Concerns expressed include how this would be implemented and how we would redefined the role of the parts specialist with the incorporation of additive manufacturing. During our midterm presentation, feedback included a suggestion that we make this app more agnostic and not tether it to a certain screened device.

With user feedback and potential technical limitations in mind, Miyeon and I continued iterating. We scrapped the kiosk concept but kept the machine learning feature, which over time collects data such as what car models break in which way more often, which technicians deliver the best results for what types of repairs, and what parts are most commonly needed. Using my prototypes and wireframes as a base, Miyeon improved the visual design while I continued work on user testing. The engineers, meanwhile, were given parts from older models to replicate via 3D printing.

the progression: user testing, iteration, and ui development

The customer mobile phone app can be found here. The service advisor tablet app can be found here. The technician tablet app can be found here.

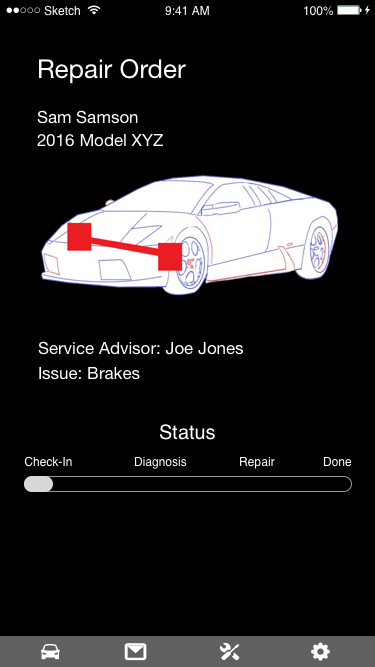

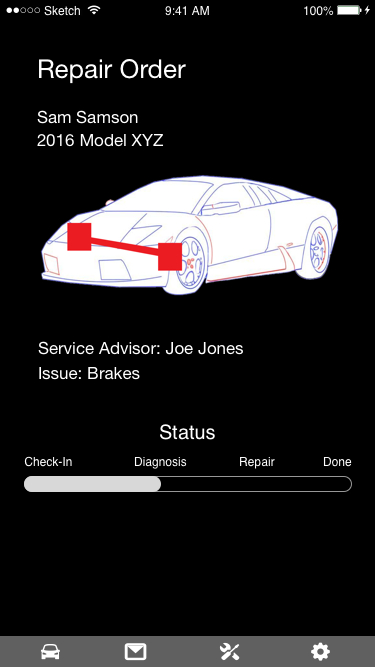

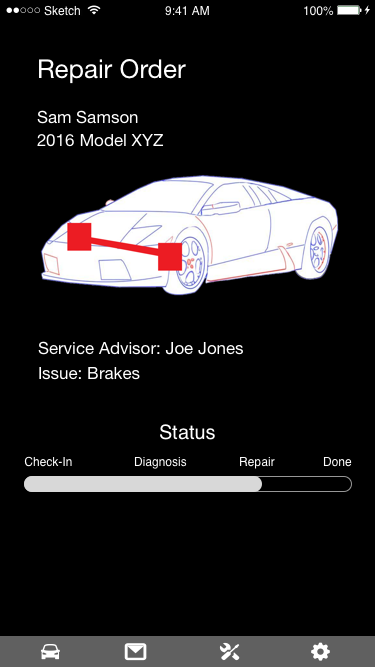

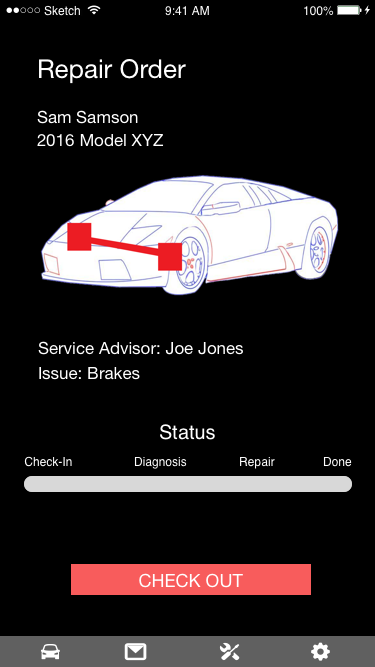

The app was adapted for three users: the customer, the service advisor, and the technician. As customers are most likely to track their vehicle's progress via mobile phone, the customer version of the app was laid out for an iPhone 8. Service advisors, who in our version of the "Workshop of Tomorrow" would have access to tablets, would use these tablets to monitor their repair jobs, order parts, and interface with the customer. The technician side of the app was created for tablet dimensions so technicians would have this mobility as well.

The main features of the app are the repair status bar, machine learning, and better visual layout. The repair status bar idea came from Amazon orders, where Amazon shows customers the status of their package, which gives the customer some security in being involved in the process. The machine learning feature tracks data from previous repair orders, part orders, and customer reviews to make the dealership more efficient overall, though we do acknowledge initial difficulties surrounding initial implementation, like how first gathering all those data points will take time. Adobe Illustrator and Marvel were used to create mockup prototypes of the app.

Positive user feedback included the following:

Users found the new system to streamline the overall process, better connecting the parties involved and keeping the customer aware of the process

The visual design was appealing (Miyeon and I research Porsche's current apps and updated their design language)

The app could be adapted to any screened device, from mobile phones to tablet to possibly desktop computers; this fit the client's desire for an "agnostic" app

Instead of working with two separate softwares and having to input the same information into both, service advisors can just use the app to cover all aspects of their job

Main concerns included the initial implementation. Our professor expressed that while we did an excellent job examining the app's output, a focus on the app's inputs needed more development. Where would the machine learning feature get all the data and information it would need to be effective? The app would require many man hours and labor from Porsche to input data and parts plans.

While the industrial designers were entrenched in user experience and visual design, the engineers developed a process for using additive manufacturing for part procurement. Through research and testing, they found that the most effective means of incorporating additive manufacturing into current processes would be to outsource the printing to 3D print vendors located within reasonable driving distances of Porsche's warehouses around the continental US.

The engineers were also given old parts to recreate via additive manufacturing. Parts with simple geometry were 3D scanned and turned into CAD files, while parts with more complex geometry (such as the HVAC box in the slideshow above) had to be manually measured with calipers and 3D-modeled in SolidWorks. The engineers then used the 3D printers at Georgia Tech to print the parts and tested them by soaking the part in gasoline to check porosity and sturdiness or checking tolerances. DFMAs and parts analyses were conducted to show how Porsche would be able to create these parts.

Overall, the engineers found that using additive manufacturing for these parts will save time and money, and would be most useful for parts for classic cars that are no longer manufactured. Once that initial CAD model of the part is made, parts specialists and technicians can create as many of those parts as needed.

the critique: what went well, what went wrong, and what i learned

This project was by far the most in-depth and difficult project I have ever undertaken. Working with engineers who come from different backgrounds and have different ways of doing things forced me out of my comfort zone, and though I did not fully understand the more technical details, I was able to learn more about parts manufacturing and cost analyses.

Here's advice I would give to anyone working on a similar project:

In a team with different strengths and personalities, communication is key. Miyeon and I are very design-oriented, often more abstract in our thinking and with a particular focus on making things look good. Working with more analytical, technical types forced us to reign in some of our more nebulous ideas and craft specifications for requirments.

During user testing, conflicting feedback will show you the bigger picture. When showing my initial wireframes, car owners really enjoyed being involved in the process while a service advisor seemed wary of having the customer always following the status bar—what if they try to micro-manage the process? This conflicting feedback highlighted the bigger issue, lack of dealership trust, and in the end I chose to keep the status bar but give more detail on individual steps.

You will never, ever have enough time. Though the project took place over the course of the whole semester, there was never enough time for any of the steps. I wish we had another week for needfinding. I wish we had a few more hours with users for testing. I wish we had a couple more days for research and preparing the presentation. Unfortunately, design always works on tight deadlines and you have to be proactive and realistic about what you can and cannot accomplish.

Overall, this project taught real-world situations, like working with technical types and dealing with deadlines, and after the IBM Styl.us it is my favorite project in this portfolio.